An air compressor is a machine that uses pressured air for a variety of purposes. It is mainly composed of a piston and cylinder. The air compressor manufacturers in ahmedabad mostly supply these machines to sectors sich as in woodworking, auto repair, furniture assembly, and construction. These sectors have a lot of work in drilling, bolting, and nailing as well as sanding, greasing, and painting. The suction of air through the inlet valve starts the compression process. After being trapped, the air is compressed by the piston and sent into a pressurized tank. The air acts as an energy source for any tool attached to the compressor in its freshly pressured state. You can also find the advanced manufacturers offering oil free air compressor India that makes the work easier for these industries.

The process is measured in two variables:

- Pounds per square inch (PSI): The amount of pressure created during compression.

- Cubic feet per minute (CFM): The rate at which air moves through the compressor.

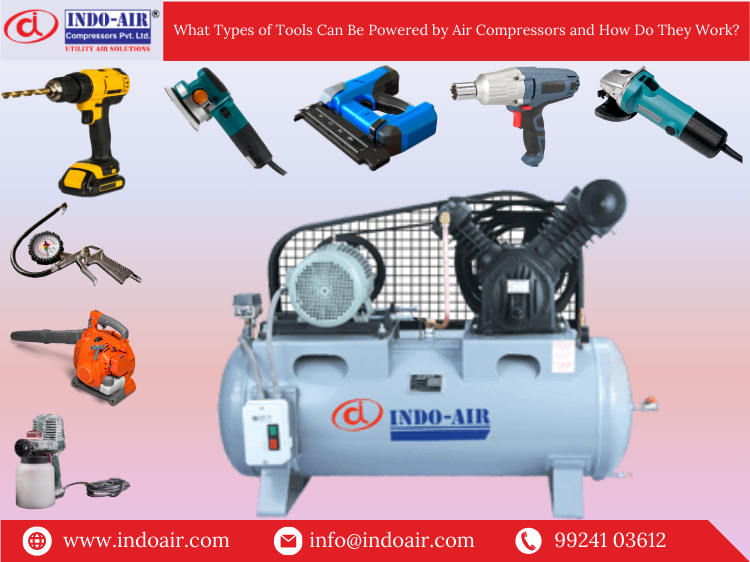

Pneumatic tools are specifically powered by air compressors. Rather than using electricity, these power tools—also referred to as air tools—operate on compressed air.

What Are Pneumatic Tools?

Air power, as opposed to electricity or batteries, powers pneumatic tools. These tools are powered by highly compressed air from air compressors. Compressed air energy is transformed into mechanical action by pneumatic motors. Tools can be set up in rotation or linearly, depending on how the airflow moves in relation to the motor. Specific airflow and pressure requirements are necessary for the operation of each tool. Pneumatic tools may operate constantly as long as there are steady air streams at the proper pressure. varying tool types require varying air volumes, and the required amount is held in corresponding air tanks. Paint sprayers, for instance, require a lot of air at low pressures, but nail guns require less air at higher pressures.

Pneumatic Tools Powered by Air Compressors

Drills: Some jobs in woodworking and construction demand more accuracy than hole drilling. A single mistake could cause a hole to become uneven, jeopardizing the entire project. A hole may be created with an air-powered drill in a quarter of the time compared to an electric drill. Boards of different thicknesses might all have deep holes made in them in a matter of seconds. The best part is that an air drill almost never overheats and can even drill holes through metal. Air pressures of an average of 3 to 6 CFM at 90 PSI are needed for drills.

Orbital Sanders: One of the most taxing woodworking activities is sanding. The grains of a sand block leave streaks in different directions along surfaces with each swipe. This issue is resolved by an orbital sander, which moves in erratic, circular directions to prevent markings from appearing on a surface in one or both directions. The average air pressure needed for orbital sanders is between 8 and 12.5 CFM at 90 PSI.

Framing Nailers: Nailing items together can be challenging for anyone with poor hand-eye coordination. Occasionally, you may hit off-target and cause damage to the board or bend the nail. In other cases, the nail might not go all the way in. These kinds of issues are resolved by using a pneumatic nailer, which can quickly and efficiently drive every nail right through, no matter how thick. Framing nailers require air pressures of an average of 2.2 CFM at 90 PSI.

Impact Wrenches: Nuts are arguably the most obstinate of all the common fasteners. The majority of the time, nuts are tightened to the maximum extent feasible in the expectation that they won’t ever come loose. In the tool trade, this very issue has given rise to a whole sector. When performing auto maintenance, a pneumatic impact wrench comes in handy for removing engine parts, lights, hubcaps, and other pieces that could be challenging to unscrew by hand.

Impact wrenches require air pressures of an average of 2.5-3.5 (3/8″), 4-5 (1/2″), 10 (1″) CFM at 90 PSI.

OtherPneumatic Tools Powered by Air Compressors

- Die Grinders

- Shears

- Tire Inflator With Gauge

- Blowers

- Paint Sprayers