In many different industries, air compressors are essential for powering tools and machinery that depend on compressed air for proper operation. The belts are one of the many parts that keep an air compressor running smoothly, yet they often seem to be disregarded. Nonetheless, as air compressor belts are essential to the machine’s general operation, the air compressor manufacturers in ahmedabad understand their significance and produce the finest ones that can be used across industries. With an efficient high pressure air compressor, there will be little disturbance in the seamless working.

Importance of Air Compressor Belts:

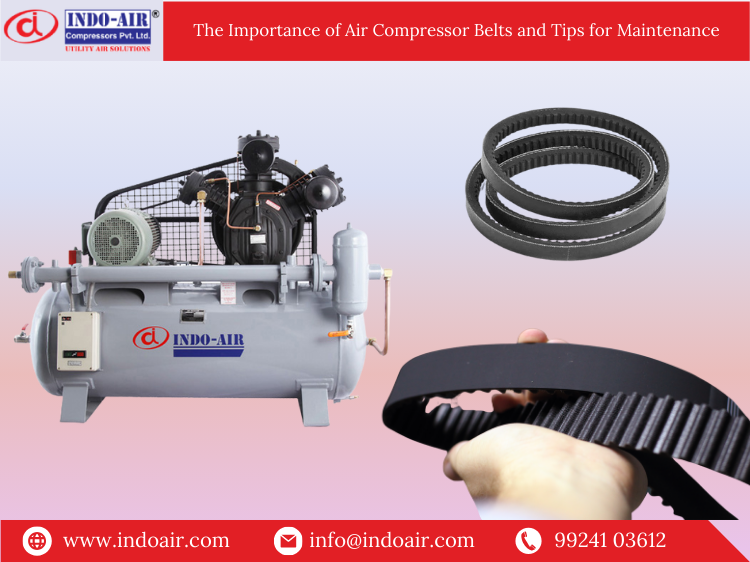

Air compressor belts are an integral part of the power transmission system in belt-driven compressors. They connect the motor to the compressor pump. It helps to transfer power to generate compressed air. The efficiency of this power transfer directly impacts the overall performance of the air compressor. A worn or damaged belt can result in reduced efficiency, increased energy consumption, and even lead to complete compressor failure.

Role of Air Compressors with Belt Drive:

Belt-driven air compressors are widely used in various applications due to their versatility and reliability. Unlike direct drive compressors, where the motor is directly connected to the pump, belt-driven compressors use a system of pulleys and belts to transfer power. Did you know that this kind of design can offer several advantages, including flexibility in speed control, lower the maintenance costs, and better shock absorption. Air compressors with belt drives are commonly found in industrial settings where a consistent and reliable source of compressed air is essential for various processes.

Maintenance and Efficient Operation

Proper maintenance is key to ensuring the longevity and efficient operation of air compressor belts. Regular inspection and timely replacement of worn or damaged belts can prevent unexpected breakdowns and maintain the overall health of the compressor. If you are looking for some essential tips for air compressor belt maintenance, here are your pointers –

- Regular Inspections: It is necessary to conduct visual inspections of the belts to check for signs of wear, cracks, or fraying. If any issues are detected, replace the belts immediately to avoid further damage.

- Tension Adjustment: Proper belt tension is crucial for efficient power transmission. Ensure that the belts are not too loose or too tight. This can be done if you consult the manufacturer’s guidelines for the recommended tension levels and adjust accordingly.

- Alignment Checks: Misalignment of belts can lead to uneven wear and reduced efficiency. Periodically check the alignment of the belts and make adjustments if necessary.

- Cleanliness: Keep the belts clean and free from debris. Dust and dirt can accelerate wear and reduce the lifespan of the belts. Regularly clean the belts to prevent unnecessary friction.

- Temperature Monitoring: Excessive heat can lead to premature belt failure. Monitor the temperature of the belts during operation and address any issues that may cause overheating.

- Replacement Schedule: Establish a routine replacement schedule for the belts, even if they appear to be in good condition. Over time, belts naturally degrade, and proactive replacement can prevent unexpected failures.

Air compressor belts may seem like a small component, but their role in the efficient operation of a compressor cannot be ignored. Regular maintenance, including inspections, tension adjustments, and timely replacements, is crucial for ensuring the longevity and reliability of air compressor belts. By giving due attention to this often-overlooked component, industries can have a consistent and efficient compressed air generation, ultimately contributing to smoother operations and increased productivity. If you are buying the air compressor from atrusted manufacturer, they will offer you with an ongoing service from the day of purchase till the time you want to continue. Maintaining the product is always a rational option than going for a new one.