Air compressors are essential in today’s world, and most sectors, such as food and beverage, pharmaceuticals, and textiles, have relied on them to grow their businesses and improve product quality. Industries that previously did not use air compressors have begun to see their potential and are gradually transitioning to air compressors these days. Air Compressor manufacturers in India have created a broad range of air compressors, and which one is best for a particular business and its needs depends on the industry. If you’re considering getting one for your company, this guide will give best tips so that you can select the right air compressor for your business knowing everything about the air compressors.

Which factors to consider while choosing the right air compressor?

There are many things one must consider while selecting the right air compressor for their business as screw compressor manufacturers design and manufacture many different types of air compressors which serve different purposes for different industries. 5 basic tips for selecting the right one for your business are given below

1. Selecting the appropriate size

- Consumer Grade

Consumer-grade air compressors, as the name implies, are those that are routinely used by ordinary people. These are tiny air compressors that are commonly used at tyre puncture businesses to inflate tyres.

- Professional Grade

Professional grade air compressors, as their name implies, are used professionally since they are larger in size than consumer grade compressors and can power many air tools because they have greater power.

- Industrial Grade

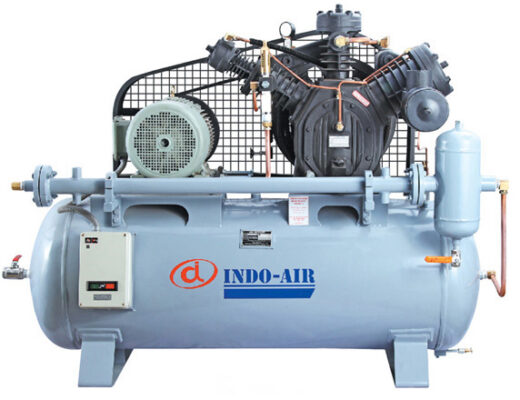

A Booster air compressor of industrial grade is the ideal choice for heavy industrial tasks since they can be used continuously and heavily. They are more robust, have a stronger structure, and do not overheat in any way. They are plainly expensive, yet they serve every purpose for which they are acquired.

2. Checking the power requirements of your job

Air compressors are available in a wide range of sizes and power outputs. Each job requires a different amount of power, and knowing how much power your job requires can assist you determine which compressor to use. An air compressor’s output is measured in cubic feet per minute (CFM), and a high CFM means you may use it to power more applications.

3. Whether an air receiver is required or not

Air receivers are used to store compressed air and are connected to compressors in the form of tanks in which the air is kept. Now, you must understand that compressors may work without air receivers as well, but this will severely limit their performance and increase the compressor’s wear and tear, so you must determine whether you want this or not. For continuous outflow pressure, an air receiver is suggested.

4. Whether an air dryer is required or not

Air dryers are used to remove water vapor and other undesired particles from compressed air, although your compressor may still function without them. However, in order to avoid corrosion and contamination, compressed air must be dried and it depends on your requirements whether you need an air dryer or not.

5.Well planned services and maintenance schedules

Even before you buy an air compressor, make sure you have a thorough conversation about its service procedures and maintenance so you don’t have to deal with any issues afterwards. Servicing and maintenance are essential components of a compressor, since they save time, money, and labor. The longevity of any machine is increased drastically when serviced and maintained properly and air compressors are not different so make sure that all services are maintained properly and timely.