Vacuum Pump 2 To 10 HP Single & Two Stage Vacuum Pumps Dry Type

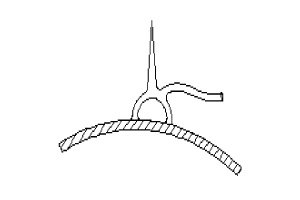

Vacuum pump is an universal design with the feature to convert it to a single stage compressor.

INDO-AIR Vacuum Pump Philosophy

- INDO-AIR Vacuum pump has a universal design with the feature to convert it to a single stage compressor. This feature is very useful for large tank leakage test under vacuum or under pressure.

- Dry type vacuum pump-only useful for handling of gases.

- Easy to install requiring, no foundation.

- Higher efficiency compared to other types or other makes of vacuum pumps.

- Low maintenance.

- Noise level under 80 DB, ideal for hospitals.

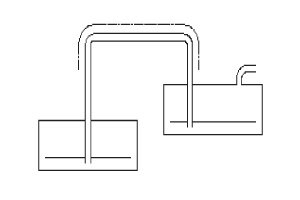

- While using liquid tanks in chemical plants for vacuum, the provision of scrubber tank is available as an additional equipment to prevent the liquid from entering the pump.

- Simple design makes it easy for any mechanic to dismantle and assemble the pump without any mismatch of the parts.

Single & Two Stage Dry Vacuum Pumps

Technical Specifications

| MODEL | MOTOR | VACUUM INCH |

RPM | WGT. KG. |

LEN mm |

WDT.

mm |

HIGHT

mm |

PISTON DISPL | |||

|---|---|---|---|---|---|---|---|---|---|---|---|

| HP | KW | CFM | M3/M | LTR/MIN | |||||||

| IA V265 | 2.0 | 1.50 | 29.0 | 960 | 84 | 740 | 406 | 432 | 21.60 | 0.610 | 610 |

| IA V265T | 2.0 | 1.50 | 29.6 | 960 | 84 | 740 | 406 | 432 | 10.80 | 0.300 | 300 |

| IA V274 | 2.0 | 1.50 | 29.0 | 866 | 145 | 1042 | 512 | 512 | 34.60 | 0.980 | 980 |

| IA V274T | 2.0 | 1.50 | 29.6 | 866 | 145 | 1042 | 512 | 512 | 17.30 | 0.490 | 490 |

| IA V285 | 5.0 | 3.70 | 29.0 | 750 | 194 | 1067 | 585 | 585 | 59.65 | 1.700 | 1700 |

| IA V285T | 5.0 | 3.70 | 29.6 | 750 | 194 | 1067 | 585 | 585 | 29.82 | 0.850 | 850 |

| IA 37V | 7.5 | 5.50 | 29.0 | 1000 | 300 | 1347 | 559 | 740 | 110.00 | 3.110 | 3110 |

| IA 37VT | 7.5 | 5.50 | 29.6 | 1000 | 300 | 1347 | 559 | 740 | 55.00 | 1.560 | 1560 |

| IA 45V | 10.0 | 7.50 | 29.0 | 900 | 398 | 1372 | 813 | 839 | 148.50 | 4.200 | 4200 |

| IA 45VT | 10.0 | 7.50 | 29.6 | 900 | 398 | 1372 | 813 | 839 | 99.00 | 2.800 | 2800 |

| MODEL | IA V265 | IA V265T |

|---|---|---|

| MOTOR HP | 2.0 | 2.0 |

| MOTOR KW | 1.50 | 1.50 |

| VACUUM INCH | 29.0 | 29.6 |

| RPM | 960 | 960 |

| WGT.KG. | 84 | 84 |

| LEN mm | 740 | 740 |

| WDT. mm | 406 | 406 |

| HIGHT mm | 432 | 432 |

| PISTON DISPL CFM | 21.60 | 10.80 |

| PISTON DISPL M3/M | 0.610 | 0.300 |

| PISTON DISPL LTR/MIN | 610 | 300 |

| MODEL | IA V274 | IA V274T |

|---|---|---|

| MOTOR HP | 2.0 | 2.0 |

| MOTOR KW | 1.50 | 1.50 |

| VACUUM INCH | 29.0 | 29.6 |

| RPM | 866 | 866 |

| WGT.KG. | 145 | 145 |

| LEN mm | 1042 | 1042 |

| WDT. mm | 512 | 512 |

| HIGHT mm | 512 | 512 |

| PISTON DISPL CFM | 34.60 | 17.30 |

| PISTON DISPL M3/M | 0.980 | 0.490 |

| PISTON DISPL LTR/MIN | 980 | 490 |

| MODEL | IA V285 | IA V285T |

|---|---|---|

| MOTOR HP | 5.0 | 5.0 |

| MOTOR KW | 3.70 | 3.70 |

| VACUUM INCH | 29.0 | 29.6 |

| RPM | 750 | 750 |

| WGT.KG. | 194 | 194 |

| LEN mm | 1067 | 1067 |

| WDT. mm | 585 | 585 |

| HIGHT mm | 585 | 585 |

| PISTON DISPL CFM | 59.65 | 29.82 |

| PISTON DISPL M3/M | 1.700 | 0.850 |

| PISTON DISPL LTR/MIN | 1700 | 850 |

| MODEL | IA 37V | IA 37VT |

|---|---|---|

| MOTOR HP | 7.5 | 7.5 |

| MOTOR KW | 5.50 | 5.50 |

| VACUUM INCH | 29.0 | 29.6 |

| RPM | 1000 | 1000 |

| WGT.KG. | 300 | 300 |

| LEN mm | 1347 | 1347 |

| WDT. mm | 559 | 559 |

| HIGHT mm | 740 | 740 |

| PISTON DISPL CFM | 110.00 | 55.00 |

| PISTON DISPL M3/M | 3.110 | 1.560 |

| PISTON DISPL LTR/MIN | 3110 | 1560 |

| MODEL | IA 45V | IA 45VT |

|---|---|---|

| MOTOR HP | 10.0 | 10.0 |

| MOTOR KW | 7.50 | 7.50 |

| VACUUM INCH | 29.0 | 29.6 |

| RPM | 900 | 900 |

| WGT.KG. | 398 | 398 |

| LEN mm | 1372 | 1372 |

| WDT. mm | 813 | 813 |

| HIGHT mm | 839 | 839 |

| PISTON DISPL CFM | 148.50 | 99.00 |

| PISTON DISPL M3/M | 4.200 | 2.800 |

| PISTON DISPL LTR/MIN | 4200 | 2800 |

Manufacturing

experience of

Years

Global

presence of

Countries

Sales & Distribution

network of

cities

Request a Free Quote

We will get back to you within 24 hrs

FAQs

Common questions we get asked about air compressors with our replies.

Trouble shooting questions are answered on another page, there links to other popular air compressor related pages to the right.

How air is Compressed ?

The atmospheric air enters the compressor at atmospheric pressure and leaves it as a high pressure at low volume gas . This process can be done by Piston or by Rotary.

Why Compressed Air is needed?

All process in indusries can not be done with atmostpheric pressure hence air is required to compress so that process can be been done.

volume of 0.818 m3; or 1 lb of air a volume of 13.07 ft3.

What are points to be considered for Compressor selection?

- Causing leakages causing facrors like rust and scale deposits in steel pipes

- Any resistance

- Improper selection of pressure controling devices in the system

- Moist in electro-magnetic controls

- Freezing of moisture in pneumatic conveying system

- Inaccurate moving parts

Why Quality of Compressed Air is Important?

- To reduce the running costs

- Easy maintenance at low costs

- Quick operation

Common impurities found in Compressed Air?

- Humidity

- Dust particles

- Oil mixed during the process by the compressor

- Gases, Vapours, Fumes.

- Bacteria/Viruses

Defination of Dew Point?

Dew point can be defined as the temperature at which air is fully saturated and below which water will condense.

How to dry the Compressed Air?

Compressed Air can be dried by two methods -

- Refrigeration

- Sorption

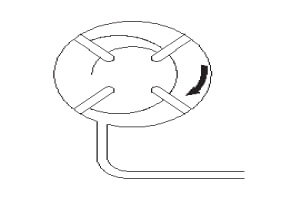

Sorption:- The air stream passes over a bed of granular desiccant which in its active state has a vapour pressure below the vapour pressure of air stream to be dried and therefore physically removes the moisture from the air stream. Sorption can be classified into Absorption and Adsorption.

Absorption:- Absorption systems use a desiccant that dissolves with the absorbed moisture. The desiccant cannot be regenerated.

Absorption:- Adsorption dryers operate by passing compressed air through a bed of desiccant material, to which the water vapour is adsorbed.. These desiccants once saturated can be regenerated and reused.

What is the basic working principle of a refrigeration Dryer?

Hot, moist air enters the refrigeration dryer through an air to air heat exchanger, where the temperature of the inlet air is reduced. This cooled air now passes through a refrigerant to air to air heat exchanger where the tempe¬rature of the air is reduced to between 2° to 5°C The cooling induces condensation and the liquid water is removed in a liquid seprator. The dry air now goes out of the dryer through the air to air heat exchange where the temperature of the air is increased to slightly below the incoming air. This is a continuous process.

The dewpoint cannot go below 2°C PDP.

What is the basic principle of the Adsorption Dryers?

There are several different types of regenerative dryers but they all conform to the same basic concept. A regenerative dryer consists of two towers filled with the desiccant. The desiccant in one bed is on stream, drying the air, while the desiccant in the other tower is being regenerated. The two towers are interlinked with switching valves so that when the desiccant in the drying tower is saturated, the valves switch the flow into the tower that has just been regenerated. This switching operation is automatic giving conti¬nuous drying.

With an adsorption dryer, very low dewpoint, down to -40°C or -60°C can be achieved.

What are Adsorbents used in the Adsorption Dryers?

- Silica Gel

- Activated Alumina

- Molecular Sieve

Application of refrigeration type air dryers?

- For general plant air, dewpoints of 2°C to 4°C are considered sufficient,

- Refrigeration type dryers use less energy and hence are lower in first and operating costs.

Our Products

Experts in the field of engineering for the compressors & vacuum pumps industry

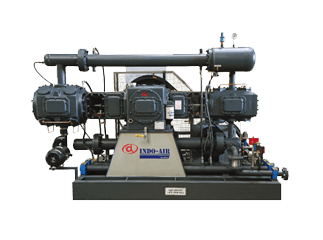

Booster Compressor 10 To 40 HP Reciprocating

Indo-Air pressurizes the air entering the compressor at 7-13 bar up to 40 bars with the IBH series booster air compressors in its production range.

Rotary Screw 7.5 To 270 HP Lubricated

Main part of Screw Compressor is Air-end, consisting of a pair of rotors. The male motor is driven by electric motor. Suction of air though Inlet filter and suction control valve.

Reciprocating Oil Free High Pressure Water-Cooled 40 To 215 HP

The search for a reliable 100% Oil Free quality air has prompted INDO-AIR to come out with totally engineered, tested and high performance range of compessors.

Oil Free Medium Pressure Water Cooled 30 To 215 HP

The search for a reliable, 100% oil free quality air has prompted Indo-Air to introduce a totally engineered, tested and high performance range of compressors.

Reciprocating 1 To 20 HP Single-Stage Low Pressure

INDO-AIR Single-stage air compressors are designed for low pressure application. These compressors have cylinders of same size (regardless of the number of cylinders).

Reciprocating 2 To 30 HP Two-Stage Medium Pressure

INDO-AIR Two - stage air compressors are designed for medium pressure application and are made of heavy-duty components to give optimum performance.

Latest Blog